Miner Adds State-of-the-Art Powder Coating Line to RPD Facility

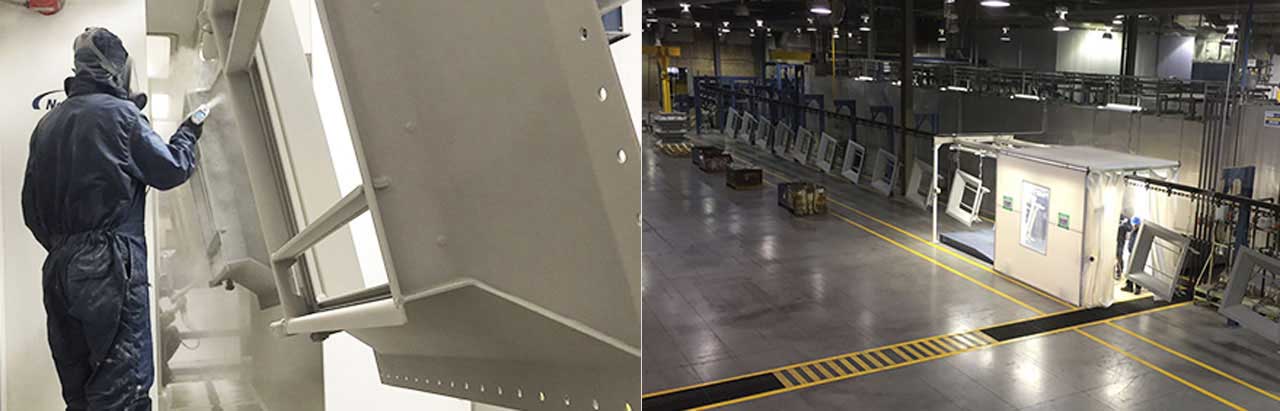

Miner Enterprises Inc. has announced a significant expansion of its production capabilities with the completion of an automated powder coating system at its Rail Products Division plant in Mexico. The system will be used to apply protective coatings to outlet gates produced at the facility.

Powder coatings, an increasingly popular alternative to traditional wet paint coatings, are valued for their high durability and visual appeal. Coatings are applied by electrostatic sprayers, then cured in ovens to ensure years of reliable performance. "We are very pleased with our new RPD powder coating line," said Ric Biehl, President and General Manager of Miner Enterprises. "Our investment in this system demonstrates Miner's commitment to meeting our customers' evolving needs."

Miner's new coating operation has the capacity to meet anticipated customer demand now and in future years. The line is highly automated and moves railcar components through a pretreatment phase, powder application, and oven curing before a final detailed inspection process. The system was designed to use reclaimed waste water and to recapture unused coating materials, making it cost-efficient and environmentally friendly.

"The majority of our customers now request powder coatings, so the time was right to add this to our core operations," said John Swezey, General Manager of Powerbrace, a Miner Subsidiary. "As opposed to relying on external shops, installing our own coating system gives us greater long-term control over quality and capacity."

The powder coating system was designed and installed by the industry's leading supplier of coating equipment. This installation represents the latest advancement in Miner's RPD facility, which recently earned the prestigious Certified Welding Fabricator accreditation for its welding operations.