TCC-45 LTRB

Preparation - Remove the metal block and clean the pocket of any foreign material. Inspect the pocket for cracks or any other damage, and repair if necessary. Insure that the pocket bottom and end walls are relatively smooth and free of any weld spatter, bumps, etc. Remove all C-Pep pads when installing constant contact side bearings.

Housing Placement: The assembly only requires one set of wedges. Center housing in pocket and insert proper wedges in both ends.

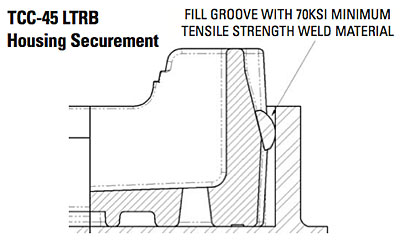

1. Make sure that the flat side of the wedge is against the Miner housing and the rounded side is against the pocket.

2. Insure that both wedges are approximately at the same height and that they do not extend beyond the housing top surface.

3. Securing the housing to the pocket requires welding. (Click here for welding requirements).

Warning: Do not weld directly to either Miner housing.

Install top cap assembly into housing with the metal cap up. Reference image below.

TCC-45 LTRB

Preparation - Remove the metal block and clean the pocket of any foreign material. Inspect the pocket for cracks or any other damage, and repair if necessary. Insure that the pocket bottom and end walls are relatively smooth and free of any weld spatter, bumps, etc. Remove all C-Pep pads when installing constant contact side bearings.

Housing Placement: The assembly only requires one set of wedges. Center housing in pocket and insert proper wedges in both ends.

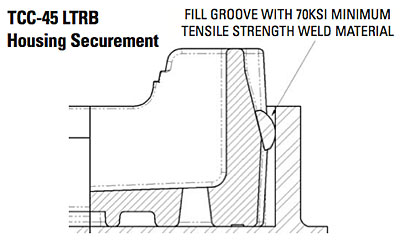

1. Make sure that the flat side of the wedge is against the Miner housing and the rounded side is against the pocket.

2. Insure that both wedges are approximately at the same height and that they do not extend beyond the housing top surface.

3. Securing the housing to the pocket requires welding. (Click here for welding requirements).

Warning: Do not weld directly to either Miner housing.

Install top cap assembly into housing with the metal cap up. Reference image below.