TCC-45 LTLP-C installation instructions for existing "low profile" bolt-on applications.

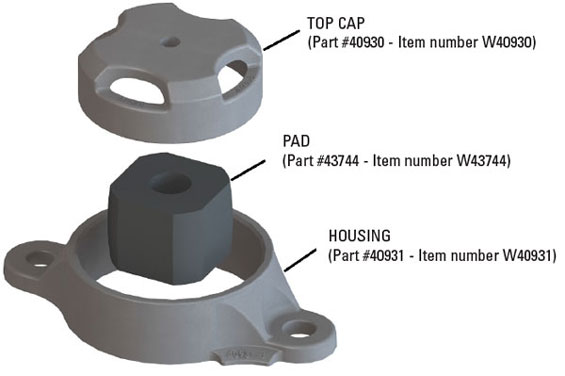

Included in each assembly are:

– one metal top cap

– one TecsPak® spring

– one bolt-on housing

Specifications:

– installed height of 2-5/8 in. (66 mm)

– 4,500 lbs. of preload

– 5/8 in. (16 mm) of travel

STEP 1 - PREPARATION

STEP 2 - SET-UP HEIGHT ADJUSTMENT

STEP 3 - HOUSING SECUREMENT

STEP 4 - FINAL ASSEMBLY

STEP 1 - PREPARATION

Pocket / Mounting Surface

- Remove the metal block and clean the pocket of any foreign material.

- Inspect the pocket for cracks or any other damage, and repair if necessary.

- Ensure that the pocket bottom and end walls are relatively smooth and free of any weld spatter, bumps, etc.

- Clean the mounting surface for bolt-on application.

Car Body Wear Plate

- The car body side bearing wear plate surface must be smooth. Any weld spatter, heavy rust or surface projections must be removed by grinding.

- Fastener heads must be smooth and not protruding below wear plate surface, and the fasteners securely tightened.

- Plates with surface variations between fastener holes greater than 1/8 in. (3 mm), or greater than 1/16 in. (1 mm) over any 4 in. (101 mm) space between the fastener holes, must be replaced.

- Surface must be reasonably parallel to side bearing mounting surface. Variations should not exceed 1/16 in. (1 mm) across width or 1/8 in. (3 mm) end to end.

Truck Centers |

Min. Width |

Min. Length |

70 ft. (21 m) or less |

4 in. (101 mm) |

12 in. (305 mm) |

70+ ft. (21 m) to 82 ft. (25 m) |

4 in. (101 mm) |

14 in. (356 mm) |

82+ ft. (25 m) to 94 ft. (29 m) |

4 in. (101 mm) |

16 in. (406 mm) |

Greater than 94 ft. (29 m) |

4 in. (101 mm) |

18 in. (458 mm) |

Please refer to AAR Manual Rule 61 for more detailed info regarding body wear plates |

||

STEP 2 - SET-UP HEIGHT ADJUSTMENT

- The LTLP-C housing is 2 in. (51 mm) tall and acts as the solid stop.

- The set-up height should be adjusted by measuring between the top of the housing and the underside of the car-body wear plate with an empty car positioned on level track before installing the top cap assembly or applying solid center plate lube.

- Car body wear plate must be large enough (see above).

STEP 3 - HOUSING SECUREMENT

Bolt-on application

- Surface must be clean and smooth and free of protrusions. Reference AAR standards:

- S-3013 Side Bearing Mounting Pad - Surface Requirements

- S-394 Side Bearing Pad for Two Hole Application

- AAR bolt hole location is 8-1/2 in. (216 mm).

- Bolt housing to bolster using appropriate fasteners and torque requirements.

Acceptable fasteners:

- Camcar standard dome head fastener (reference part #794-20100-130)

- Huck fastener (reference part #C71LR-BR24-28/32 and #3LC-2R24GL).

- 7/8"-9 Grade 5 or better HEX head bolt with self-locking nut.

Torque:

- Dry: 375-425 ft.-lbs. (Produces a clamping force of 20,000-30,000 lbs. per bolt).

- Waxed or well lubricated threads: 280-320 ft.-lbs. (Roughly 25% reduction from dry values).

STEP 4 - FINAL ASSEMBLY

1. Place TecsPak® pad inside the housing.

2. Place top cap on pad. There is a male end on top cap that should go inside the female end of the pad.

TCC-45 LTLP-C installation instructions for existing "low profile" bolt-on applications.

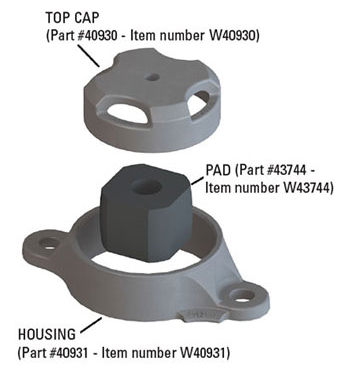

Included in each assembly are:

– one metal top cap

– one TecsPak® spring

– one bolt-on housing

Specifications:

– installed height of 2-5/8 in. (66 mm)

– 4,500 lbs. of preload

– 5/8 in. (16 mm) of travel

STEP 1 - PREPARATION

STEP 2 - SET-UP HEIGHT ADJUSTMENT

STEP 3 - HOUSING SECUREMENT

STEP 4 - FINAL ASSEMBLY

STEP 1 - PREPARATION

Pocket / Mounting Surface

- Remove the metal block and clean the pocket of any foreign material.

- Inspect the pocket for cracks or any other damage, and repair if necessary.

- Ensure that the pocket bottom and end walls are relatively smooth and free of any weld spatter, bumps, etc.

- Clean the mounting surface for bolt-on application.

Car Body Wear Plate

- The car body side bearing wear plate surface must be smooth. Any weld spatter, heavy rust or surface projections must be removed by grinding.

- Fastener heads must be smooth and not protruding below wear plate surface, and the fasteners securely tightened.

- Plates with surface variations between fastener holes greater than 1/8 in. (3 mm), or greater than 1/16 in. (1 mm) over any 4 in. (101 mm) space between the fastener holes, must be replaced.

- Surface must be reasonably parallel to side bearing mounting surface. Variations should not exceed 1/16 in. (1 mm) across width or 1/8 in. (3 mm) end to end.

Truck Centers |

Min. Width |

Min. Length |

70 ft. (21 m) or less |

4 in. (101 mm) |

12 in. (305 mm) |

70+ ft. (21 m) to 82 ft. (25 m) |

4 in. (101 mm) |

14 in. (356 mm) |

82+ ft. (25 m) to 94 ft. (29 m) |

4 in. (101 mm) |

16 in. (406 mm) |

Greater than 94 ft. (29 m) |

4 in. (101 mm) |

18 in. (458 mm) |

Please refer to AAR Manual Rule 61 for more detailed info regarding body wear plates |

||

STEP 2 - SET-UP HEIGHT ADJUSTMENT

- The LTLP-C housing is 2 in. (51 mm) tall and acts as the solid stop.

- The set-up height should be adjusted by measuring between the top of the housing and the underside of the car-body wear plate with an empty car positioned on level track before installing the top cap assembly or applying solid center plate lube.

- Car body wear plate must be large enough (see above).

STEP 3 - HOUSING SECUREMENT

Bolt-on application

- Surface must be clean and smooth and free of protrusions. Reference AAR standards:

- S-3013 Side Bearing Mounting Pad - Surface Requirements

- S-394 Side Bearing Pad for Two Hole Application

- AAR bolt hole location is 8-1/2 in. (216 mm).

- Bolt housing to bolster using appropriate fasteners and torque requirements.

Acceptable fasteners:

- Camcar standard dome head fastener (reference part #794-20100-130)

- Huck fastener (reference part #C71LR-BR24-28/32 and #3LC-2R24GL).

- 7/8"-9 Grade 5 or better HEX head bolt with self-locking nut.

Torque:

- Dry: 375-425 ft.-lbs. (Produces a clamping force of 20,000-30,000 lbs. per bolt).

- Waxed or well lubricated threads: 280-320 ft.-lbs. (Roughly 25% reduction from dry values).

STEP 4 - FINAL ASSEMBLY

1. Place TecsPak® pad inside the housing.

2. Place top cap on pad. There is a male end on top cap that should go inside the female end of the pad.