TCC-LTLP-B

Pocket Size Adjustment

Inside Length - If the wedges hit the pocket floor before contacting the end wall (inside length roughly greater than 9-5/8"), shim application is required. Optimal inside length after shimming should be 9-3/8". Fabricate the shim so that it is 1/4" shorter than the pocket wall and no wider than the flat portion of the end wall. Leave enough room on the shim width for welding. Fillet weld the shim to one end of the pocket using 70-ksi minimum tensile strength weld material.

If the pocket has oval cut outs at the each end of it, it is recommended, if space is available, that shims be inserted to each end to insure a good surface to weld the wedge too.

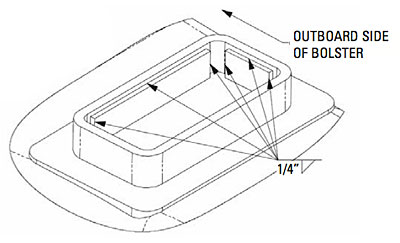

Inside Width: If the inside width of the pocket exceeds 4-5/8", shimming will be required. Estimate the shim thickness needed to reduce the pocket width to between 4-1/4" and 4-1/2". Fabricate the shim so that it is approximately 1/4" shorter than the pocket wall and no longer than the flat portion of the pocket side wall. Leave enough room on the shim length for welding. Fillet weld the shim to the outboard side of the pocket using 70-ksi minimum tensile strength weld material.

Inside Width: If the inside width of the pocket exceeds 4-5/8", shimming will be required. Estimate the shim thickness needed to reduce the pocket width to between 4-1/4" and 4-1/2". Fabricate the shim so that it is approximately 1/4" shorter than the pocket wall and no longer than the flat portion of the pocket side wall. Leave enough room on the shim length for welding. Fillet weld the shim to the outboard side of the pocket using 70-ksi minimum tensile strength weld material.

TCC-LTLP-B

Pocket Size Adjustment

Inside Length - If the wedges hit the pocket floor before contacting the end wall (inside length roughly greater than 9-5/8"), shim application is required. Optimal inside length after shimming should be 9-3/8". Fabricate the shim so that it is 1/4" shorter than the pocket wall and no wider than the flat portion of the end wall. Leave enough room on the shim width for welding. Fillet weld the shim to one end of the pocket using 70-ksi minimum tensile strength weld material.

If the pocket has oval cut outs at the each end of it, it is recommended, if space is available, that shims be inserted to each end to insure a good surface to weld the wedge too.

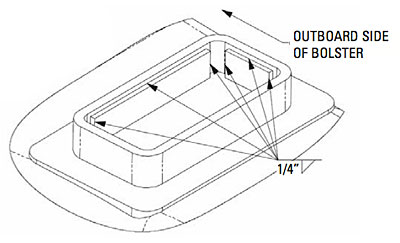

Inside Width: If the inside width of the pocket exceeds 4-5/8", shimming will be required. Estimate the shim thickness needed to reduce the pocket width to between 4-1/4" and 4-1/2". Fabricate the shim so that it is approximately 1/4" shorter than the pocket wall and no longer than the flat portion of the pocket side wall. Leave enough room on the shim length for welding. Fillet weld the shim to the outboard side of the pocket using 70-ksi minimum tensile strength weld material.

Inside Width: If the inside width of the pocket exceeds 4-5/8", shimming will be required. Estimate the shim thickness needed to reduce the pocket width to between 4-1/4" and 4-1/2". Fabricate the shim so that it is approximately 1/4" shorter than the pocket wall and no longer than the flat portion of the pocket side wall. Leave enough room on the shim length for welding. Fillet weld the shim to the outboard side of the pocket using 70-ksi minimum tensile strength weld material.