Alternate Set Up Height

Miner side bearings allow greater flexibility in the set up height. On some articulated intermodal cars, at the male location of the articulated connection, the side bearing can have a set up height of 5-1/16 in. -1/16 in. (129-132mm). On selected autorack cars, the long travel side bearing can have a set up height of 5-1/16 in.-1/8 in. (129-130mm). (Refer to owners' instructions, or stenciling, on these types of cars.) If a new elastomeric horizontal center bowl liner is used, it is recommended that you add 1/16 in. (1.6mm) to the nominal dimension.

Block Style Retrofit Set Up Height

| Models | Installation or Adjustment | |

TCC 45 LTLP, |

Metal Liner |

New Non-Metallic Liner or Lube Disc |

Nominal Tolerance |

Nominal Tolerance |

|

5/8 in. ± 1/16 in. (16 ± 1.6 mm) |

11/16 in. ± 1/16 in. (17.5 ± 1.6 mm) |

|

Range |

||

Max: 11/16 in. (17.5mm) |

Max: 3/4 in. (19 mm) |

|

Min: 9/16 in. (14 mm) |

Min: 5/8 in. (16 mm) |

|

The housing must extend a minimum of 1/16 in. (1.6mm), up to a maximum of 3/8 in. (9.5mm), beyond the top of the pocket wall around the entire perimeter.

If the pocket wall is taller than any housing, either:

• Add steel shims under the bottom of the housing covering the entire pocket floor;

or

• Remove enough material from the top of wall to insure the 1/16 in. (1.6mm) minimum extension.

In some cases, adjusting the shim thickness is not an option. It is permissible to use a 3/8 in. (9.5mm) wear plate on certain cars according to AAR Field Manual Rule 61 E.2.

Other cases may require shimming of the center bowl. Please refer to AAR Field Manual Rule 47 for specifics on the center bowl shimming.

Block Style Retrofit Set Up Height Gage

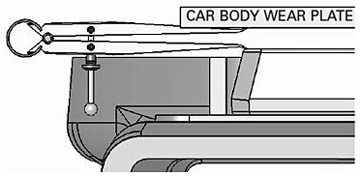

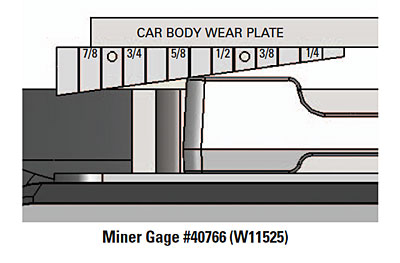

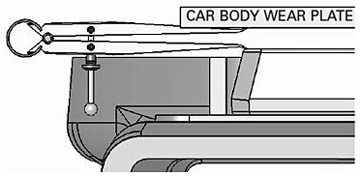

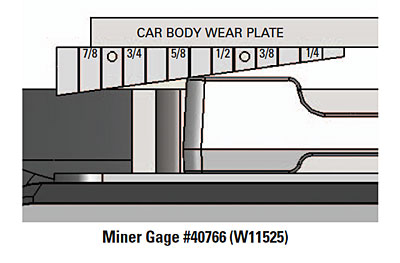

Miner's #40766-B (W11525) triangular aluminum gage is designed to be used for set up height check and adjustment for the TCC-45 LTLP, LTLP-B and LTRB constant contact side bearings. The gage face ranges from 3/16 in. (5mm) to 1 in. (25mm) in 1/16 in. (1.6mm) increments. The desired distance between the housing and the car body wear plate is 5/8 in. (16mm) - 1/16in. (1.6mm). If an elastomeric horizontal center bowl liner is used, add 1/16 in. (1.6mm) to the nominal dimension. So the desired distance would become 11/16in. (17.5mm) -1/16 in. (1.6mm).

To check the set up height, put flat end of gage up to the car body wear plate and slide the gage in until it contacts the housing. If the gap is below 5/8 in. (16mm) then remove the correct amount of shims and if the gap is above 5/8 in. (16mm) add the correct amount of shims. The gage has 1/8 in. (3 mm) increments lined and labeled with 1/16in. (1.6mm) increments lined, but not labeled. The thickness of the gage is 1/8 in. (3 mm) and can be used as the smallest measurement increment on the gage. Simply turn the gage flat and put one side against the wear plate and slide the gage in.

Alternate Set Up Height

Miner side bearings allow greater flexibility in the set up height. On some articulated intermodal cars, at the male location of the articulated connection, the side bearing can have a set up height of 5-1/16 in. -1/16 in. (129-132mm). On selected autorack cars, the long travel side bearing can have a set up height of 5-1/16 in.-1/8 in. (129-130mm). (Refer to owners' instructions, or stenciling, on these types of cars.) If a new elastomeric horizontal center bowl liner is used, it is recommended that you add 1/16 in. (1.6mm) to the nominal dimension.

Block Style Retrofit Set Up Height

| Models | Installation or Adjustment | |

TCC 45 LTLP, |

Metal Liner |

New Non-Metallic Liner or Lube Disc |

Nominal Tolerance |

Nominal Tolerance |

|

5/8 in. ± 1/16 in. (16 ± 1.6 mm) |

11/16 in. ± 1/16 in. (17.5 ± 1.6 mm) |

|

Range |

||

Max: 11/16 in. (17.5mm) |

Max: 3/4 in. (19 mm) |

|

Min: 9/16 in. (14 mm) |

Min: 5/8 in. (16 mm) |

|

The housing must extend a minimum of 1/16 in. (1.6mm), up to a maximum of 3/8 in. (9.5mm), beyond the top of the pocket wall around the entire perimeter.

If the pocket wall is taller than any housing, either:

• Add steel shims under the bottom of the housing covering the entire pocket floor;

or

• Remove enough material from the top of wall to insure the 1/16 in. (1.6mm) minimum extension.

In some cases, adjusting the shim thickness is not an option. It is permissible to use a 3/8 in. (9.5mm) wear plate on certain cars according to AAR Field Manual Rule 61 E.2.

Other cases may require shimming of the center bowl. Please refer to AAR Field Manual Rule 47 for specifics on the center bowl shimming.

Block Style Retrofit Set Up Height Gage

Miner's #40766-B (W11525) triangular aluminum gage is designed to be used for set up height check and adjustment for the TCC-45 LTLP, LTLP-B and LTRB constant contact side bearings. The gage face ranges from 3/16 in. (5mm) to 1 in. (25mm) in 1/16 in. (1.6mm) increments. The desired distance between the housing and the car body wear plate is 5/8 in. (16mm) - 1/16in. (1.6mm). If an elastomeric horizontal center bowl liner is used, add 1/16 in. (1.6mm) to the nominal dimension. So the desired distance would become 11/16in. (17.5mm) -1/16 in. (1.6mm).

To check the set up height, put flat end of gage up to the car body wear plate and slide the gage in until it contacts the housing. If the gap is below 5/8 in. (16mm) then remove the correct amount of shims and if the gap is above 5/8 in. (16mm) add the correct amount of shims. The gage has 1/8 in. (3 mm) increments lined and labeled with 1/16in. (1.6mm) increments lined, but not labeled. The thickness of the gage is 1/8 in. (3 mm) and can be used as the smallest measurement increment on the gage. Simply turn the gage flat and put one side against the wear plate and slide the gage in.